Daejeon, South Korea: In one of the most bizarre inventions, researchers have been able to devise a new to make wiring for electronics that can bend and stretch by zapping liquid metal droplets with ultrasound.

The crazy technique, connecting liquid metals with a sound which is described in the Nov. 11 issue of Science Journal, gives researchers another tool in their arsenal as they create circuitry for wearable electronics, medical sensors that adhere to the skin, and other applications where stiff circuit electronics are less ideal.

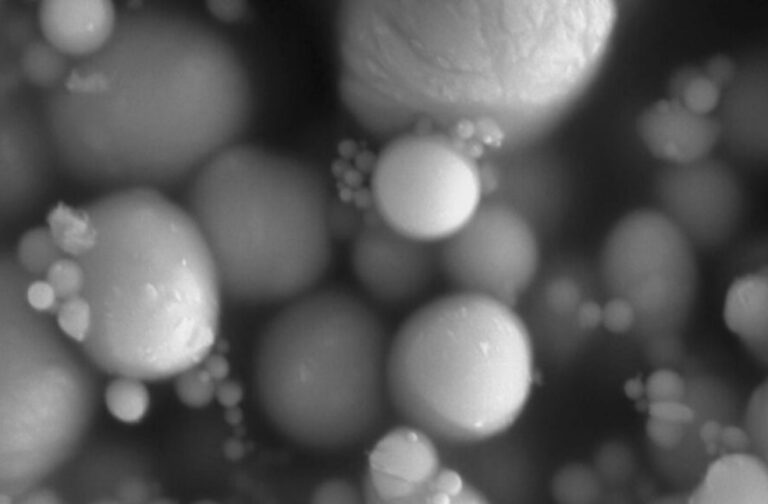

The researchers started by making lines of small droplets formed from an alloy of gallium and indium on sheets of flexible plastic. When temperatures rise above 16 degrees Celsius, the metal alloy becomes liquid. The droplets of liquid metal swiftly oxidize despite being electrically conducting. Each of them receives a thin insulating coating as a result of that operation. Static charges on the layers push the drops apart, so they can’t be used to connect LEDs, microchips, and other parts of an electrical circuit.

The scientists used high-frequency sound waves to impact the microspheres, causing them to shed even smaller, nanoscopic balls of liquid metal. The smaller spheres fill in the spaces between the larger ones, and their close contact with the oxide layers lets electrons tunnel through them and send energy through the droplets. The larger metal balls can flex when the plastic that the drops are printed on is stretched or bent, while the smaller ones behave like hard particles that move around to maintain contact.

By combining electronics into a stretchable pattern of LEDs that displayed the initials of the Dynamic Materials Design Laboratory, where the study was done, the researchers showcased their conductors. The group also created a conductor-equipped sensor that can track blood flow through a person’s skin.

According to materials scientist, Dr. Jiheong Kang of the Korea Advanced Institute of Science and Technology in Daejeon, South Korea, flexible electronics applications are nothing new.

However, Dr. Kang claims that this novel strategy has advantages over previous models, such as ones that rely on liquid metal channels that may leak if the circuitry is broken. Dr. Kang and his team made conductors with little spheres inside that catch liquid metal and keep it there even if the plastic is torn.

Mr. Carmel Majidi, a Mechanical Engineering expert at Carnegie Mellon University in Pittsburgh who was not involved with the current study, pointed out that liquid metal wires have frequently been the preferred conductors for stretchy electronics.

There is a “novel approach to achieving that conductivity” introduced by the use of ultrasound in the research. According to Mr. Majidi, other teams have achieved that feat by heating, laser-exposing, squishing, vibrating, or squashing circuits to cause droplets to join with one another.